When it comes to outfitting your workplace with industrial lockers, it can be easy to overlook some important considerations. After all, they seem like a simple and straightforward addition to your workplace, right? However, there are some common mistakes that businesses make when purchasing industrial lockers for their employees, and avoiding these mistakes can save you a lot of headaches in the long run. In this blog, we’ll take a look at 5 mistakes to avoid when purchasing new lockers for your workplace.

1.

Neglecting

Employee Needs

The

first mistake to avoid when purchasing new industrial lockers for your

workplace is neglecting the needs of your employees. After all, these lockers

are going to be used by your employees every day, so it’s important that they

meet their needs. Take the time to assess your employees’ needs and

preferences, and choose lockers that are functional and practical for them. For

example, if you have employees who need to store large tools or equipment,

consider purchasing lockers that have enough space and are designed to hold

heavy items. Alternatively, if your employees prefer lockers with built-in

locks, be sure to choose models that offer this feature.

2.

Failing

to Consider Space Constraints

Another

common mistake that businesses make when purchasing industrial lockers

is failing to consider space constraints. It’s important to choose lockers that

fit your workplace, both in terms of size and layout. Before making a purchase,

take measurements of the space where you plan to install the lockers and ensure

that the lockers you choose will fit comfortably in the available space.

Additionally, consider how the lockers will be arranged in the space to

maximize efficiency and ease of use for your employees.

3.

Overlooking

Locker Security

Industrial

employees’ lockers are an important investment for any workplace, and it’s

important to ensure that they are secure. This means choosing employee lockers that are built to withstand potential security breaches, such as

tampering or theft. When purchasing lockers, consider the level of security

they offer, such as the type of locks used and the materials used in

construction. Additionally, consider the layout of your workplace and choose

lockers that are placed in areas that are easily visible to your employees and

surveillance cameras.

4.

Ignoring

Compliance Standards

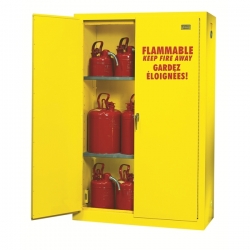

Compliance

is an important consideration when it comes to purchasing these lockers. There

are various compliance standards and regulations that must be met to ensure the

safety and security of your employees, as well as compliance with local laws

and regulations. As such, it’s important to choose lockers that meet these

standards and to ensure that they are installed and used in compliance with

relevant regulations. For example, Compliance Solutions Canada is a trusted

provider of industrial lockers that are designed to meet various compliance

standards and regulations.

5.

Underestimating

Maintenance Needs

Finally,

it’s important to consider the maintenance needs of your industrial lockers

when making a purchase. Like any other piece of equipment, lockers require

regular maintenance to ensure that they remain in good condition and function

properly. When purchasing lockers, consider the maintenance requirements, such

as cleaning and upkeep, and ensure that your employees are trained on how to

properly care for the lockers. Additionally, be sure to choose lockers that are

made from durable materials and are built to last, to minimize the need for

frequent repairs or replacement.

What are the compliance standards for Employees Locker in Canada?

In

Canada, compliance standards for employee lockers typically include

requirements related to safety, security, and accessibility. These standards

can vary depending on the type of workplace and the industry in which it

operates but may include requirements related to the materials used in locker

construction, the type of locks used, the placement of lockers within the workplace,

and accessibility requirements for employees with disabilities.

The Wrap

In

a nutshell, industrial lockers are an important addition to any

workplace, and it’s important to take the time to choose lockers that are

functional, secure, compliant, and easy to maintain. By avoiding these common

mistakes, you can ensure that your employees have the lockers they need to

store their belongings safely and securely and that your workplace remains

efficient and compliant. And remember, Compliance Solutions Canada is your

trusted partner when it comes to choosing high-quality, compliant best

employees locker in Canada.