There is no doubt that handling and storing materials is an essential part of any industrial setting. It means the right materials should be available at the right place and time. That is where efficient material handling and storage play a key role. In addition, safety storage ensures that workplace employees in any industrial environment have sufficient raw material quality to do their job.

Handling

and storing the material is hard and brings new challenges. Luckily this issue

can be tackled efficiently. Here are the tips that will help improve safety and

storage in common industrial settings.

Use

Specialized Material Racks

As per

the OSHA guidelines, the material handling and storage encourages employees to

keep the material on racks and to stack and prevent it from sliding, falling, and collapsing.

Although

three are multiple highly specialized material racks for the material for your

warehouse. The right solution here would be to choose the right products and

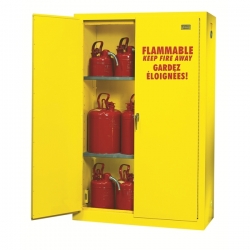

storage racks to support each product in your facility. Visit Compliance

Solutions if you are looking for storage cabinets in Canada.

Know Your Weight Limits

The

next step is to check the match-safe storage rack for your industrial setting.

Again, it would help if you stayed within the designated weight limit.

This means that your storage racks should be made from heavy-duty steel, as the weight limits generally exceed what is planned for storage. weight limit

Don’t

Over a stack

You

should never overstack kegs and drums barrels on top of each other; instead,

you can always use pallets or wooden planks between the layers. But, again, it

helps to create a flat surface for the upper layers.

Block

Stacks of Cylindrical Materials

Steel

bars and pipe poles come with unique storage challenges. If placed on the wrong

racks, they can easily roll over on others, posing a dangerous avalanche of

heavy materials. It is why OSHA blocks stack the cylindrical on each other.

OSHA

recommends stacks of lumber at 16 feet high in applications so workers can

handle these materials manually.

Provide

Personal Protection Equipment

Heavy

machinery and moving equipment are commonly seen in warehouses and

manufacturing facilities. These are open invitations to injury if you haven't

taken the appropriate safety measures. Often, these procedures entail arming

your personnel with personal safety gear.

Employees who want to keep themselves safe while working or using specific equipment should wear personal protection equipment (PPE). This gear may consist of heavy-duty boots, gloves, fireproof jackets, and helmets. Depending on the unique requirements of your warehouse, certain items of equipment will change. You must offer this protection to everyone who requires it, regardless of the circumstance may require.

Wrap

Up

There

can be high costs involved in material handling. Improper handling and storage

can lead to accidents. It would help if you always stocked your warehouse with

safe and efficient storage solutions. If you are looking for a safety storage system? Visit Compliance solution Canada. We offer solutions that protect

people and property with products that meet Canadian Federal and Provincial

Standards.

No comments:

Post a Comment